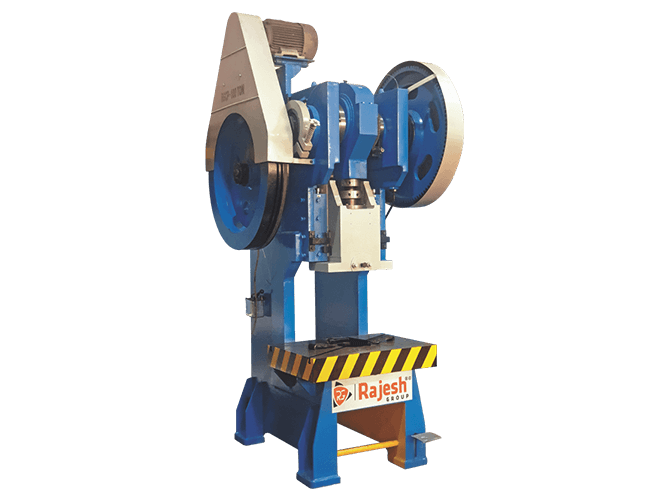

In the world of manufacturing and industrial processes, efficiency, accuracy, and safety are paramount. One machine that has revolutionized these aspects is the Mechanical Power Press Machine. This versatile device plays a crucial role in shaping various materials, from metals to plastics, by applying force through a mechanical mechanism. Visit: Mechanical Power Press

Understanding the Mechanical Power Press Machine:

The Mechanical Power Press Machine, also known as a mechanical press, is a powerful device designed to convert rotational motion into linear force. It operates on the principle of mechanical advantage, where force is multiplied through the use of gears, levers, and linkages. The machine is equipped with a ram, which delivers the necessary force to shape or form the material being processed. Explore: NC Press Brake Machine

Applications of the Mechanical Power Press:

The versatility of the Mechanical Power Press Machine makes it indispensable in a wide range of industries. Some common applications include:

Metal Forming:

In metalworking, the power press machine excels at tasks such as blanking, bending, punching, stamping, and coining. It is used to shape metal sheets and produce intricate components used in automotive, aerospace, and appliance manufacturing, among others.

Plastic and Rubber Processing:

The power press machine finds its utility in the plastic and rubber industries for tasks like compression moulding, deep drawing, and extrusion. It enables the production of various plastic and rubber products, such as containers, gaskets, and seals.

Assembly and Riveting:

With the ability to deliver controlled and consistent force, power presses are widely used in assembly operations, including riveting, fastening, and joining of components. This ensures a secure and efficient assembly process, improving product quality and reducing production time.

Benefits of the Mechanical Power Press Machine:

The Mechanical Power Press offers several advantages that make it a preferred choice in manufacturing facilities:

Enhanced Productivity:

By automating repetitive tasks, the power press machine significantly increases productivity. It can exert a high force repeatedly and accurately, reducing human error and improving overall efficiency.

Precise and Consistent Results:

With adjustable settings and precise control mechanisms, the power press machine delivers consistent results. This is particularly important in applications requiring tight tolerances and uniformity of the final products.

Cost-Effective Operations:

The power press machine streamlines production processes, reducing labour costs and material waste. Its high-speed capabilities and low maintenance requirements contribute to cost-effective operations.

Conclusion:

The Mechanical Power Press Machine has revolutionized the manufacturing industry by providing efficient, precise, and cost-effective solutions for a variety of applications. Its ability to shape and form materials with high force and accuracy has made it an indispensable tool across numerous sectors. By adhering to safety guidelines and proper maintenance, this machine continues to drive progress and productivity in the modern industrial landscape.

Read About: Navigating the Pathway to Canada: A Guide to the Express Entry System