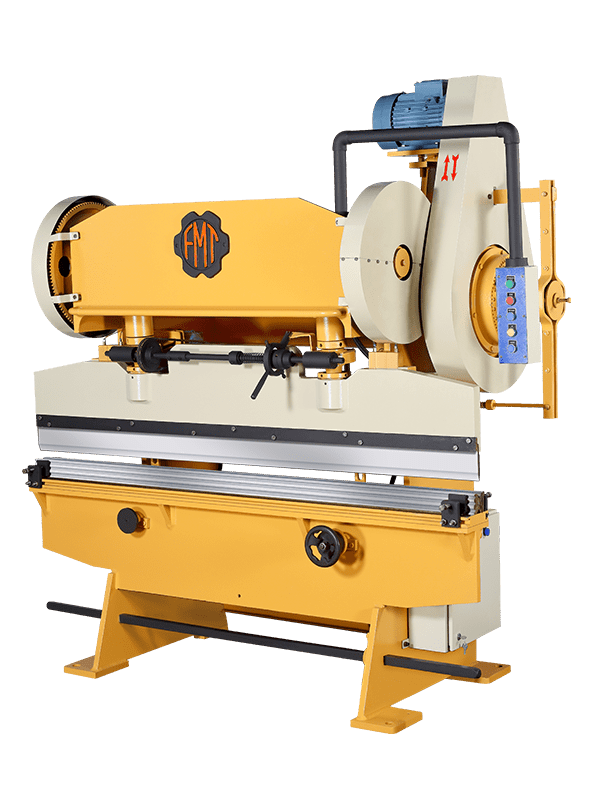

A press brake machine is a versatile and essential tool used in the metalworking and fabrication industries. It is designed to bend and shape sheet metal or plate material into various forms, angles, and configurations. The press brake machine applies force through hydraulic or mechanical mechanisms to create precise and accurate bends in the metal. Visit: Press Brake Machine Manufacturers

Here are some key features and benefits of a press brake machine:

Flexibility

Press brake machines can handle a wide range of metal thicknesses and lengths. They offer flexibility in terms of the angles and shapes that can be achieved, making them suitable for a variety of applications and industries.

Precision and Accuracy

These machines are equipped with advanced control systems that allow for precise and repeatable bending operations. The ability to set and control parameters such as bend angle, back gauge position, and tonnage ensures consistent and accurate results. Explore: Power Press Machine Manufacturers

Versatile Tooling Options

Press brake machines can accommodate various tooling options, such as punches and dies, which enable the creation of different bend profiles and shapes. This versatility allows for customization and adaptability to specific project requirements.

Increased Productivity

With their efficient bending capabilities, press brake machines significantly enhance productivity in metalworking operations. They can handle multiple bends in a single setup, reducing the need for manual repositioning and minimizing production time.

Cost-effective Solution

By eliminating the need for manual bending and reducing material waste, press brake machines offer cost savings and improved efficiency. The precise control over the bending process also reduces errors and rework, optimizing resource utilization and maximizing profitability.

Safety Features

Modern press brake machines are equipped with safety features, such as light curtains, interlocks, and emergency stop systems, to ensure operator safety during operation. These safety measures minimize the risk of accidents and create a secure working environment.

Automation Integration

Many press brake machines can be integrated into automated production lines, allowing for seamless material handling, bending, and stacking operations. This integration further enhances productivity and efficiency in large-scale manufacturing processes.

In summary, a press brake machine is an indispensable tool for the metalworking and fabrication industries. Its flexibility, precision, versatility, and productivity-enhancing features make it a valuable asset for bending and shaping sheet metal or plate material. Whether it’s for small-scale projects or large-scale manufacturing, a press brake machine offers efficient and accurate bending solutions, contributing to the success and competitiveness of metalworking operations.

Read About: All About Garments