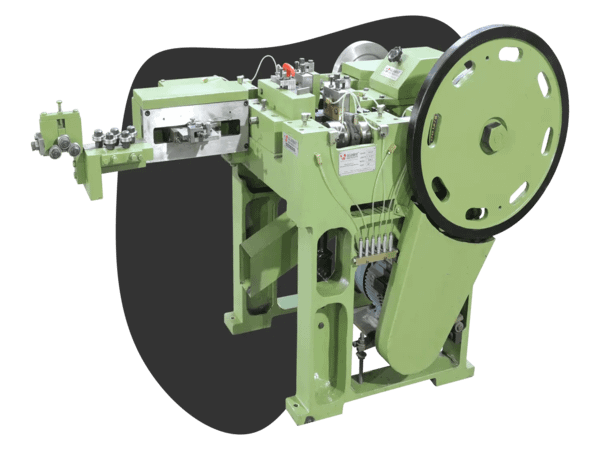

A Wire Nail Producing Machine, also known as a wire nail-making machine, is a mechanical device designed to efficiently and automatically manufacture wire nails. These machines are widely used in the construction, woodworking, and manufacturing industries to produce nails of various sizes and types. Visit: Wire Nail Making Machine

The wire nail-producing machine operates by taking in a coil of wire as input material. The wire is fed into the machine, where it undergoes a series of processes to transform it into nails. Here are the key steps involved in the wire nail production process:

Wire Feeding

The coil of wire is unwound and fed into the machine through a wire-feeding mechanism. The wire is typically made of materials such as steel or iron, which provide the necessary strength and durability for nails.

Wire Straightening

The wire passes through a straightening mechanism to ensure it is properly aligned and free of any bends or kinks. This step helps in achieving consistent nail quality and prevents issues during the subsequent stages. Explore: High Speed Wire Nail Making Machine

Wire Cutting

The straightened wire is cut into individual nail lengths by a cutting mechanism. The machine can be set to produce nails of specific lengths, allowing for customization based on application requirements.

Nail Head Formation

The cut wire is then fed into a nail head-forming section. Here, the wire is shaped to create the head of the nail, which can be flat, round, or another desired shape. The head formation process can involve various techniques, including punching, rolling, or moulding.

Nail Point Formation

After the head formation, the wire is further processed to create the pointed end of the nail. This can be done through a grinding or sharpening mechanism, which shapes the wire tip into a sharp point suitable for penetrating surfaces.

Nail Polishing

Some wire nail-producing machines may include a polishing barrel drum as an additional step. This drum rotates the nails inside, polishing their surfaces and enhancing their appearance.

Nail Collection and Packaging

Once the nails are fully formed, they are collected in a container or conveyor belt for further processing or packaging. Depending on the specific requirements, the nails can be bundled, boxed, or prepared for distribution in other ways.

Wire nail-producing machines vary in size, capacity, and automation level, ranging from manual or semi-automatic machines to fully automated systems capable of high-speed production. These machines offer significant advantages, including increased production efficiency, consistent nail quality, and reduced labour costs compared to manual nail production.

In conclusion, a wire nail-producing machine is a specialized mechanical device used to automate the manufacturing process of wire nails. By efficiently transforming wire coils into finished nails, these machines play a crucial role in meeting the demand for nails in various industries.

Read About: About CNC Machine