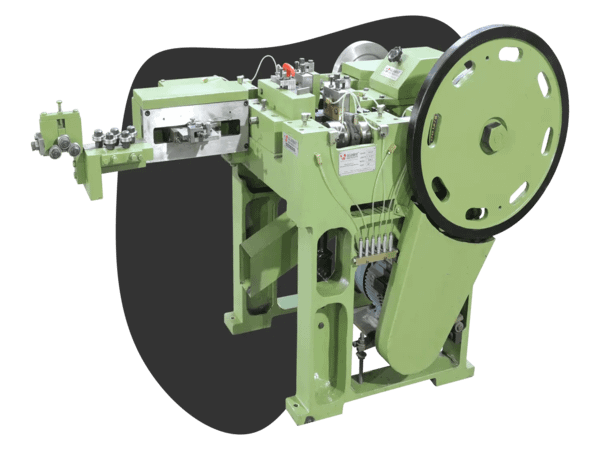

Wire Nail Manufacturing Machine

A wire nail manufacturing machine is specialized equipment used in the production of wire nails. It automates the process of transforming wire coils into finished nails of various sizes and types. We design these machines to streamline the manufacturing process and improve productivity by efficiently and precisely forming, cutting, and polishing wire nails. Visit: Automatic High Speed Wire Nail Making Machine

Here are some key features and benefits of a wire nail manufacturing machine:

High-Speed Production

Wire nail machines are capable of producing nails at high speeds, significantly increasing the output compared to manual nail production. They can rapidly feed, form, cut, and polish nails, ensuring a continuous and efficient manufacturing process.

Automatic Operation

These machines have advanced automation features that reduce the need for manual intervention and minimize labor requirements. They can perform various operations, such as wire feeding, nail forming, cutting, and polishing, with minimal human involvement. Visit: N1 Nail Machine

Versatility in Nail Sizes and Types

Wire nail manufacturing machines can produce a wide range of nail sizes and types, including common nails, roofing nails, concrete nails, panel pins, coil nails, spiral nails, and more. By adjusting the machine settings and tooling, different nail specifications can be easily accommodated.

Precision and Consistency

The use of wire nail manufacturing machines ensures consistent nail quality and precise dimensions. The machines deliver accurate nail shapes, lengths, and diameters, meeting the required specifications and industry standards.

Cost-effective and Efficient

By automating the nail production process, wire nail manufacturing machines offer cost savings and improved efficiency. They minimize material waste, reduce labour costs, and optimize production speed, resulting in higher productivity and profitability.

Customization Options

Some wire nail machines provide flexibility for customization, allowing manufacturers to produce nails with specific features or branding requirements. This adaptability enables businesses to meet the unique needs of their customers and cater to specialized markets.

Ease of Maintenance

Wire nail manufacturing machines are built to withstand heavy-duty usage and are designed for easy maintenance. Routine maintenance procedures and regular inspections ensure the longevity and reliability of the machine, minimizing downtime and maximizing productivity.

In summary, a wire nail manufacturing machine is a valuable investment for nail production businesses. Its high-speed production, automation capabilities, versatility, precision, and cost-effectiveness make it an essential tool in the manufacturing process. By utilizing these machines, manufacturers can optimize nail production, enhance product quality, and meet the demands of the market efficiently.

Read More: Overview of Hydraulic CNC Machine