The wire nail making process involves several steps to transform raw wire material into finished wire nails. Let’s explore the various stages involved in wire nail production:

Wire Material Selection

The process begins with selecting the appropriate wire material. Commonly used materials for wire nails include mild steel, stainless steel, or galvanized steel wire. The wire should have the necessary strength and durability to withstand the nail manufacturing process and the intended application of the nails. Visit: High Speed Wire Nail Making Machine Manufacturer

Wire Cleaning and Straightening

We thoroughly clean the selected wire to remove any impurities or contaminants, and then we use specialized machinery to straighten it, ensuring it is in the correct shape and alignment for the subsequent processes.

Wire Cutting

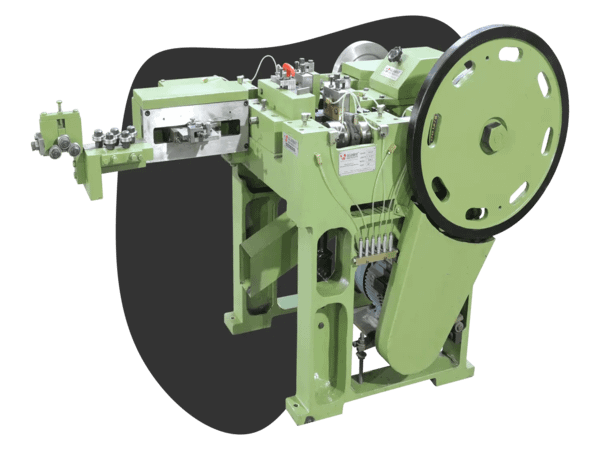

In this step, we cut the straightened wire into desired lengths based on the required nail size. We commonly use automatic wire nail making machines for efficient and precise wire cutting. The machine cuts the wire into individual nail blanks, ready for the shaping process. Explore: Wire Nail Making Machine Manufacturer

Nail Head Formation

The nail head formation is the next crucial step in the wire nail making process. The nail blanks are fed into a nail-making machine that has a specific head-forming mechanism. The machine shapes the head of the nail by applying pressure and force to the nail blank, creating the desired head shape, such as flat, round, or countersunk.

Pointing

After the head formation, the nail blanks proceed to the pointing stage. Pointing involves sharpening one end of the nail to form a pointed tip. This process enhances the nail’s ability to penetrate various materials effectively. Pointing can be achieved using specialized machinery or manual grinding techniques, depending on the scale of production.

Polishing

Once the wire nails are formed and pointed, they may undergo a polishing process. Polishing helps to enhance the appearance of the nails by removing any rough edges, burrs, or imperfections. This step can be performed using polishing barrels or drums, which utilize tumbling action and abrasives to achieve a smooth and shiny finish on the nails.

Coating (Optional)

Depending on the specific requirements or intended use of the wire nails, they may undergo a coating process. Coatings like galvanization or electroplating provide additional protection against rust and corrosion, particularly for nails used in outdoor or humid environments.

Packaging

The final step in the wire nail making process involves packaging the finished nails for distribution and sale. We sort and package the nails in suitable containers, such as boxes or bags, according to the desired quantity and packaging specifications.

We implement quality control measures throughout the nail producing process to ensure the nails meet industry standards and customer requirements. This includes regular inspections, measurements, and tests to verify dimensions, strength, and overall nail quality.

By following these steps, manufacturers can efficiently produce wire nails that meet the demands of various industries, such as construction, woodworking, and manufacturing. The wire nail making process combines precision, automation, and quality control to deliver reliable and durable nails for a wide range of applications.

Read About: Overview of Vegetable Cutter Machine